The factors of the unbalance of the serpentine spring coupling and the method to reduce the fracture

蛇形弹簧联轴器靠蛇形弹簧片来传递扭矩,是当今国 际机械领 域 先 进的轴联接传动部件,也是一种非常通用的轴联接传动部件。

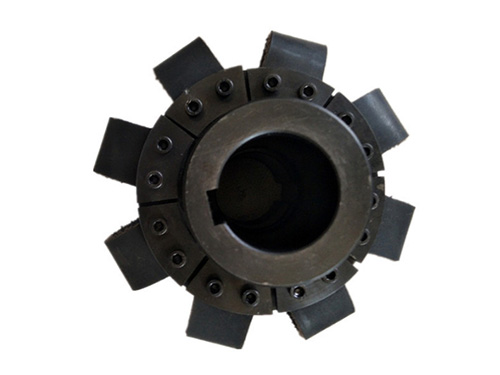

The main structure of the serpentine spring coupling is composed of two half couplings, two half outer covers, two sealing rings and a serpentine spring sheet.It transfers torque by embedding the serpentine spring into the tooth slots of the two coupling halves, and the coupling uses serpentine spring sheets to be embedded in the tooth slots of the two coupling halves to realize the link between the driving shaft and the driven shaft.During operation, the driven end is driven by the axial force of the active end tooth facing the snake spring to transmit torque, which largely avoids the occurrence of resonance phenomenon and the elastic variable generated by the reed when transmitting torque , So that the mechanical system can obtain a better damping effect, with an average damping rate of more than 36%.

Serpentine spring coupling其主要结构是由两个半联轴节,两个半外罩,两个密封圈及蛇形弹簧片组成。

一、蛇形弹簧联轴器有以下优点:

(1) Good vibration damping and long service life

(2)承受变动载荷范围大,起动安 全

(3)传动效 率 高,运行可 靠

(4) Low noise and good lubrication

(5) Simple structure, convenient assembly and disassembly

(6) The whole machine has few parts, small size and light weight

(7) Large installation deviation is allowed.

二、为减少蛇簧片的断裂,应力求做到以下几点:

(1) Pay attention to adjusting the concentricity error and angle error between the two shafts, and make it as small as possible than the value required by the design.

(2)提高弹簧片的质量。特别要注意材质、硬度、热处理质量等,热处理后不应有裂纹等缺陷存在,注意清 除簧片和齿角边上尖角和尖棱);提高弧形齿面的加工质量。

(3) Choose lubricating grease reasonably, not using thinner lubricating oil, but using aluminum disulfide grease with higher viscosity.

(4) To control the load, do not use overload; reduce the frequent effect of braking, especially emergency braking.

(5)在换新时,应采用新型弹性棒销型联轴器。

三、蛇形弹簧联轴器的潜在不平衡因素:

蛇形弹簧联轴器主要采用铸造特种钢。为适应特 殊需要而炼制的合金铸钢,品种繁多,通常含有一种或多种的高量合金元素,以获得某种特 殊性能。例如,含锰11%~14%的高锰钢能耐冲击磨损,多用于矿山机械、工程机械的耐 磨零件;以铬或铬镍为主要合金元素的各种不锈钢,用于在有腐蚀或650℃以上高温条件下工作的零件,如化工用阀体、泵、容器或大容量电站的汽轮机壳体等。任意一个联轴器组件的平衡等级是根据联轴器的惯性主轴线与旋转轴线之间重心位置偏心量的大可能值的平方和方根值而决定的。其不平衡量以微米表示。对联轴器组件的潜在不平衡因素前面作了介绍,确定各种类型联轴器组件的平衡等级和计算平衡的各个步骤见计算示例。(1)联轴器选用者应选择适当的联轴器平衡等级,轴承、轴承座、底座的刚性:机械传动系统对旋转零件来说,具有挠性底座或支架,对联轴器的不平衡状态较敏感。(2)联轴器不平衡量的大小能否满足任一种旋转系统的需要,则取决于每一种特 殊的被联接机器的性能,由生产被联接机器的制造厂来确定。建议各机器制造厂在提供其设备的同时,也拟订好适当的挠性联轴器平衡等;(3)若不能从机器制造厂得 到适当的联轴器的等级。轴向偏移:若某机械的轴伸较长或挠性大,则对联轴器不平衡状态比较敏感。由联轴器重量引起的轴承载荷与轴承总载荷之间的关系:若某机械选用轻载轴承或联轴器载荷基本上由联轴器的悬臂负荷引起的,则此机械对联轴器的不平衡状态较敏感,具有悬臂转子或悬臂负荷的机械装置,通常联轴器的不平衡状态比较敏感。