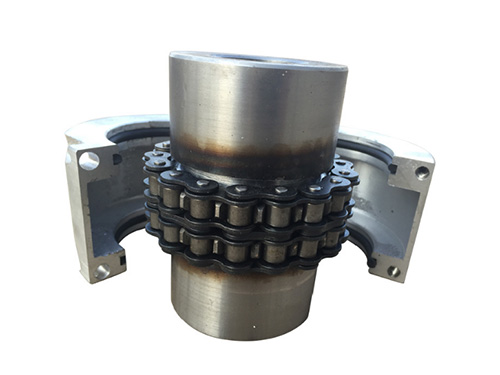

Common faults and maintenance methods of drum gear coupling

一、常见故障

1. The center deviation of the drum gear coupling is too large, and the relative displacement of the tooth surface is large;

2. Poor material and low tooth surface hardness;

3. Insufficient lubrication or dry grinding;

4. The oil is not clean;

5. The tooth profile design of the drum gear coupling is not reasonable enough, the tooth top interferes or the machining accuracy is not high;

6. Excessive installation interference causes the tooth head clearance to disappear;

7. The oil is of poor quality, and the oil contains acids or sulfides.

Two, the solution

1、先校正中心;

2. Choose suitable materials, and the hardness of the tooth surface after treatment is about 50-60;

3. Check the amount of oil and make the position where the lubricating oil pipe is aligned;

4、过滤油,使油含杂质的大粒度小于25um;

5. Use drum-shaped teeth with good performance;

6. Install various drum-shaped gear couplings as required, and check the radial clearance of the inner and outer teeth;

7、替换润滑油等等。

三、曲线要求

鼓形齿式联轴器对鼓度曲线有何要求?非共轭齿面的鼓形齿面是由不同端截面逐渐变位相叠而成,其变位量与轴向坐标形成的虚线叫鼓度曲线,鼓度曲线是鼓形齿式联轴器的一项重要几何参数。鼓度曲线多为一段圆弧,也有用三段圆弧的,这些圆称为鼓度圆,在圆弧鼓度曲线中,有鼓度圆中心在齿轮轴线上的,有不在轴线上的;有鼓度圆中心与齿面球面中心重合的,也有不重合的,通常设计是都以经验为主,总的来说,鼓形齿式联轴器应达到以下要求:

(1)在轴间倾角处于大时不出现棱边接触现象;

(2) The smaller the gear tooth's concentrated load, the better, and the curvature of the tooth surface is proportional to the circumference of the drum, so the drum radius is as large as possible.The curvature radius of the bulge curve is proportional to the single-sided thinning of the internal tooth, so the bulge circle radius should be as large as possible.The radius of curvature of the bulge curve is proportional to the single-sided thinning of the internal tooth, that is, it is related to the meshing gap of the tooth. Insufficient thinning may cause interference, and excessive thinning will weaken the strength of the tooth, and the backlash will be large. .

四、内齿周期

浅谈NGCL型带制动轮鼓形齿式联轴器内外齿周期性,Drum gear coupling在工作时,两轴产生相对角位移,内外齿的齿面周期性作轴向相对滑动,必然形成齿面磨损和功率消耗,因此,鼓形齿式联轴器需在有良好和密封的状态下工作。鼓形齿式联轴器径向尺寸小

NGCL型带制动轮鼓形齿式联轴器是由齿数相同的内齿圈和带外齿的凸缘半联轴器等零件组成。外齿分为直齿和鼓形齿两种齿形,所谓鼓形齿即为将外齿制成球面,球面中心在齿轮轴线上,齿侧间隙较一般齿轮大,鼓形齿联轴器可允许较大的角位移(相对于直齿联轴器),可改 善齿的接触条件,提高传递转矩的能力,延长使用寿命。

五、保养方法

良好的润滑是鼓形齿式联轴器安 全可 靠运行的必 要 保 证,也是减缓磨损。在齿根弯曲强度和齿面接触强度足够的条件下应以有较大的重合度来确定齿宽,不应盲目增加齿宽,以免使结构尺寸不必 要的增加。一般齿宽系数为8-14。小齿宽应由允许的齿根应力来确定,还要考虑由轴间倾角引起的着力点沿齿宽位移所需要的宽度。

提高WGT型中间套鼓形齿式联轴器使用寿命的重要途径。齿宽系数影响轮齿的齿根弯曲强度和齿面接触强度,齿宽系数越大,这两项强度越大,齿宽系数影响重合度,在齿宽系数小于一 定值的范围时,其值的增大对重合度增加影响较大,而在大于这个一 定值时,器值的增大对重合度增加影响变小,对于圆弧鼓度曲线的鼓形齿式联轴器,齿宽还是确定鼓度圆半径也侧隙的参数,齿宽越大,鼓度圆半径越大,所需要的侧隙也越大。