Installation steps and precautions of snake spring coupling

虽然我国挠性联轴器设备采用钛合金材料的是刚刚起步,但实践证明,钛合金是一种经过长期考验、理想的蛇簧联轴器用材料,钛合金密度低,比强 度 高、具有一 定的耐 腐 蚀能力,这些优点可提高产品整体性能。为使钛合金材料能够稳定及广泛地应用于挠性联轴器设备,还需要使用方、设计单位、材料研制及生产单位、机组制造及维修厂的通力合作,以便长期地积累钛合金材料的使用数据和经验。

随着挠性联轴器技术的发展、钛合金锻造及加工工艺的不断完善改进以及制约我国钛合金产业发展瓶颈的突破,我们相信钛合金材料在挠性联轴器设备上将会有着越来越广泛的应用前景。

随着挠性联轴器技术的发展、钛合金锻造及加工工艺的不断完善改进以及制约我国钛合金产业发展瓶颈的突破,我们相信钛合金材料在挠性联轴器设备上将会有着越来越广泛的应用前景。

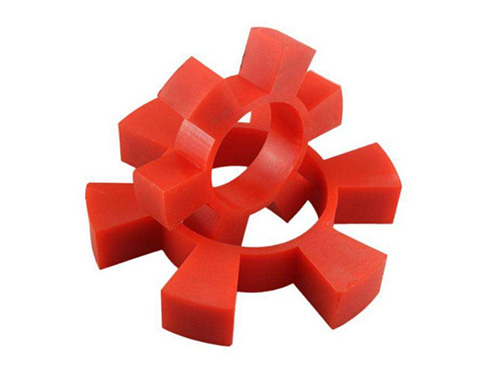

Snake spring coupling is a mechanical part used to connect two shafts (driving shaft and driven shaft) in different mechanisms so that they can rotate together to transmit torque.In high-speed and heavy-load power transmission, some couplings also have the function of buffering, damping and improving the dynamic performance of the shafting.The coupling is composed of two halves, which are respectively connected with the driving shaft and the driven shaft.The general power machine is mostly connected with the working machine by means of a coupling.

Couplings belong to the category of general mechanical parts and components, and are commonly used connecting parts for shaft transmission of mechanical products.Commonly used couplings include diaphragm couplings, gear couplings, plum couplings, slider couplings, drum gear couplings, universal couplings, couplings, flexible couplings And serpentine spring coupling.

What are the precautions during the installation, use and maintenance of the coupling?Let's come here for everyone.

Coupling installation steps

1. Install the half-piece coupling on the shaft

(1) According to the size of the coupling, measure the actual (composition) elements of the shaft and the hole, and draw the line of the loading end position according to the regulations.

(2) Hammering method.Used for small size and clearance fit.First apply lubricating oil on the fit, place the key in the keyway, align the half-piece coupling into the shaft, and hit it with a hammer (preferably hit on the middle pad) until it is installed in the final position.

(3)压力机装配。用于有过盈的配合,当过盈较大时,用温差法配合压力机装配。温差法装配是将孔(半片联轴器)加热膨胀后,再装在轴上。可用润滑油在加热箱内加热,或用蒸汽加热、电加热等,也可用冷却轴使直径变小,再装配上Snake spring coupling。冷装用的冷却剂有液氮(冷却温度可达-190~195℃)、液氨(冷却温度可达-120℃)、干冰加酒精和丙酮(冷却温度达-75℃)。

2. Coupling alignment connection

After the coupling is installed on the journal, the two halves of the coupling are preliminarily aligned by adjusting the shim, so that the centers of the two shafts are roughly aligned, and the end faces of the two coupling halves are initially parallel, and then the bolts are put on to prepare for coaxial Degree adjustment.

Things to note

(1)蛇簧联轴器与轴装配时,要符合设备技术文件或施工验收规范的规定,并保持端面间隙,但刚性凸缘式联轴器端面不允许存在间隙。

(2)装配时,可根据联轴器的尺寸,在轴颈上作出装入深 度标记,以避免装入过量。

(3)开始装入时,要先保持联轴器端面与轴的轴线垂直,再开始锤击或压入,以防止产生偏心。

(4)用油加热热装时,油与火要隔离,防止起火,加热地点应无易燃物品。