Operation and damping performance of star elastic coupling

弹性联轴器是用来轴系的运行情况,调整传动装置轴系扭转振动特性,补偿振动、冲击所引起的主、从动机轴线位移,并不间断地传递转矩和运动的一种扭转弹性复合橡胶联轴器装置。它具有很高的弹性和的阻尼,能补偿连接机构的轴向位移、径向位移和角度的角位移,并能够较好地解决轴系的扭振问题,起到缓冲减振和降低噪声等作用。广泛用于船舶、重型汽车等行业的柴油机动力装置及具有较大干扰力矩的传动装置轴系中,实现减振降噪的目的,并起到保护主、从动机和提高整个传动装置运行性的作用。

The elastic element is the key component of the elastic coupling. It can absorb energy to attenuate vibration and alleviate impact; at the same time, its high elasticity and low stiffness physical properties can help realize displacement compensation and greatly adjust the natural frequency of the transmission device to avoid resonance and The purpose of reducing structure noise.Therefore, the development of elastic elements largely determines the development of elastic couplings.

The elastic element is the key component of the elastic coupling. It can absorb energy to attenuate vibration and alleviate impact; at the same time, its high elasticity and low stiffness physical properties can help realize displacement compensation and greatly adjust the natural frequency of the transmission device to avoid resonance and The purpose of reducing structure noise.Therefore, the development of elastic elements largely determines the development of elastic couplings.

At present, elastic couplings are classified according to elastic elements, mainly two categories: metal elastic element elastic coupling and non-metal elastic element elastic coupling.

金属弹性元件弹性联轴器主要有膜片联轴器、蛇形弹簧联轴器等,其共同的特点是疲劳强 度 高,承载能力大,好,使用寿命长,性能稳定,动力性能容易控制,但制造要求严格,成本较高。

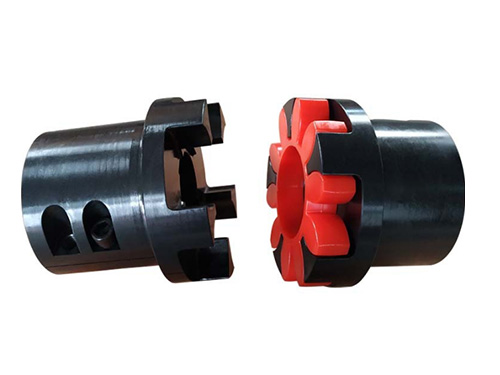

Non-metallic elastic element elastic pin couplings mainly include elastic sleeve pin couplings, plum-shaped elastic couplings, tire couplings, etc. The common features are small mass, easy molding, large internal friction, and damping. Good performance, high variable performance per unit volume storage, no mechanical friction, no lubrication, but low strength, poor high and low temperature resistance.

The elastic element is a key component of the elastic coupling. It can produce significant elastic deformation when loaded. On the one hand, it plays a role in compensating the relative displacement between the two connected shafts, and secondly, it can buffer the elastic deformation by storing it. Third, the natural frequency of the system can be adjusted by changing the structural rigidity of the coupling to reduce vibration and avoid resonance.Therefore, to design an elastic coupling with excellent transmission performance, the key is to design the elastic elements in it.

为了适应各类机器的工作要求,联轴器的改进和发展一直受到人们的重视。在中小转矩和环境比较恶劣的条件下,我们多的是采用非金属弹性元件的Flexible coupling。常用的非金属弹性元件有橡胶弹性元件和工程塑料弹性元件,而橡胶弹性元件应用为广泛。

联轴器在减速机设备上的应用特点

联轴器作为传动装置中的零部件,减速机上,它也是不可缺少的。联轴器在减速机上的安装的时候要留意以下几点:

1.法兰梅花形联轴器排油槽的油应能排除,加快机应平稳地安装在不乱程度的底子或底座上。且冷却氛围轮回流畅。底子不可 靠,联轴器运转时会引起振动及噪声,并促使轴承及齿轮受损。当传动毗连件有凸起物或采用齿轮、链轮传动时,应试虑加装防护装置,输出轴上承受较大的径向载荷时,应选用加强型。

2.联轴器不应用锤子敲击,凡把持组装夹具和轴真个内螺纹,用螺栓将传动件压入,否则有可以或许造成加快机内部零件的破坏。较好联轴器不采用钢性固定式联轴器,因该类输出轴上装配传动件时。联轴器装配欠妥,会引起毋庸要的外加载荷,甚至造成轴承的早期破坏,严峻时甚至造成输出轴的断裂。

3.联轴器安装减速机时,应正视传动轴线对中,其误差不得大于所用联轴器的使用补偿量。对联轴器中良好能延长使用寿命,并获得理想的传动效率。