Snake spring coupling advantages and simple installation method

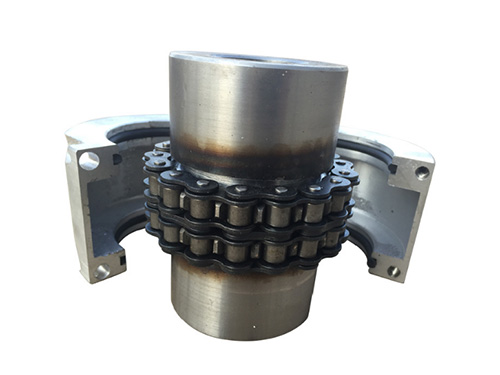

Snake spring coupling is also called slider coupling, which consists of two half couplings with grooves on the end faces and a middle disc with convex teeth on both sides.Because the convex teeth can slide in the groove, the relative displacement between the two shafts during installation and operation can be compensated.The snake spring coupling uses polyurethane plastic as the elastic element and the two-half coupling body is tightly combined. (Assembly picture) The main body is made of 45# steel, and there are also stainless steel bodies, which can be customized according to customer requirements.The material is well-proportioned, avoiding uneven rotation caused by uneven material.The surface is blackened and anti-rust treatment. (Main body comparison chart) The intermediate polyurethane plastic element is formulated with a unique formula, which has high temperature resistance, good toughness, and stable quality with ordinary ordinary plastic parts (comparison chart of advantages and disadvantages).The plastic component has a star shape.Snake spring couplings are widely used in general machinery, hydraulic machinery, engineering machinery, metallurgical machinery, mining machinery, chemical machinery and many other occasions. XNUMX. Advantages of Snake Spring Coupling

XNUMX. Advantages of Snake Spring Coupling

1. The main shaft sleeve is made of aluminum alloy, which is lightweight

2、中间十字滑块可供多种不同颜色选择

3、安装方便、免维护、可抗油污和电气绝缘

4. Simple structure, high torque, high rigidity, high sensitivity coupling

5. Allow large radial and axial deviations

6. Absorb relatively high transmission torque

7、寿命长,性能

8. Not suitable for high-speed transmission field

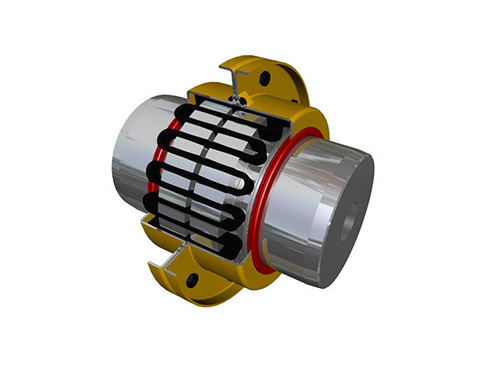

9、制作工艺:精车件,表面处理:本色氧化处理Snake spring couplingIt can compensate the axial, radial and angular deviations between the active machine and the driven machine caused by manufacturing errors, installation errors, load-bearing deformations and the effects of temperature rise changes.The diaphragm coupling is a flexible coupling with a metal elastic element. It relies on the metal coupling diaphragm to connect the main and driven machines to transmit torque. It has the advantages of elastic vibration damping, no noise, and no need for lubrication. Ideal product for type coupling and general coupling.

Second, the correct selection of the snake spring coupling, its simple installation method is

1. Fastening bolt type: This low-cost type is a traditional fixing method.However, the front end of the bolt is in direct contact with the end center, which may cause damage to the shaft or difficulty in disassembly.Snake spring coupling

2. Clamping type: Use the tightening force of countersunk bolts to shrink the slit and clamp the shaft tightly.It is convenient to fix and disassemble, and will not damage the axis of Qiancheng.

3、分离型:分离型的特点是具有 分开的轴套,蛇簧联轴器可以不用移动装置而达到固定,拆卸的目的。

4. Semi-separable type: One side of this type is a clamping type bushing, and the other side is a separate type bushing. First fix one side of the shaft to the clamping type shaft sleeve, and then install the shaft center at the device end. In the separable bushing.

5、键槽型:这种类型与紧固螺栓型一样,是 比较传统的固定方式,适合较高扭力矩的传动,为防止轴向移动,通常与紧固螺栓型,夹持型并用。

三、如何正确选用蛇簧联轴器的适用范围;

1. Elastic snake spring coupling: suitable for rotary encoders and stepping motors.

2. Diaphragm snake spring coupling: suitable for servo motors and stepping motors.

3. Corrugated tube serpentine coupling: suitable for servo motors.

4. Slider snake spring coupling: suitable for ordinary micro motors.

5. Plum blossom snake spring coupling: suitable for servo motors and stepping motors.

6. Rigid snake spring coupling: suitable for servo motors and stepping motors.