Product Series

PRODUCT CATEGORY

-

Diaphragm coupling>

-

Henan drum gear coupling>

-

Henan roller chain coupling>

-

Henan plum blossom elastic coupling>

-

Henan star coupling>

-

Henan elastic pin coupling>

-

Henan elastic sleeve pin coupling>

-

Henan tire coupling>

-

Henan serpentine spring coupling>

-

Henan nylon gear coupling>

-

Henan Slider Coupling>

-

Henan clamp shell coupling>

-

Henan rigid coupling>

-

Henan elastic pin gear coupling>

-

Henan coupling accessories>

Industry News

NEWS

- Selection of requirements and grade determination of serpentine spring coupling

- Pay attention to the problems and scope of application when installing the star coupling

- Heat treatment status and disassembly work of star coupling

- The phenomenon that the elastic pin coupling is prone to long processing time

- Talking about the Analysis of the Damage Causes of the Star Coupling

Henan JSB serpentine spring coupling

TAG

The curved tooth surface on the serpentine reed and the outer gear sleeve of the JS B serpentine spring coupling is difficult to manufacture due to its complex shape.When manufacturing snake reeds, not only more forming molds are required, but also the dimensional accuracy is difficult to meet the design requirements.The formation of the snake spring is achieved by using a mold under heating, and then heat treatment. During the heat treatment, the arc of the reed is prone to problems such as micro cracks.Since the serpentine spring coupling is hot-assembled under high temperature and tension, it is necessary to fully estimate the problems that may occur.

JS B serpentine spring couplingFrequently possible accidents include the axis of the coupling skewed and the coupling can’t advance. In order to prevent such accidents, it is necessary to be correct when calibrating the axis, the position of the coupling hole and the shaft, and the position of the striker. Also note that the location of the impact point should be selected, one or two hits should be light, and only after a certain distance (about 1/3) of the person can be slammed.If it is indeed skewed and cannot be calibrated, it should be pulled out after being heated again, and never slammed into it.Pay attention to the fact that the block pulley moves backward due to the improper position, the hoist chain slips down, the fuel is insufficient, and the fire alarm.

Check carefully during the tool preparation and operation training phase.When the bearing, mechanical seal and other components have been installed on the main shaft in advance, it is forbidden to hit and hit the coupling forcefully to prevent damage or damage to the components.You should try to avoid it beforehand. If it happens, you will not panic on the spot and take timely measures to deal with it.First, let each operator understand the operation steps, achieve a clear division of labor, and stick to their posts in the event of any accident.Secondly, it is required to calibrate the axis of the coupling to be horizontal or vertical, and to align the position of the coupling hole and the shaft end.When adjusting the position of the striker, you must be careful, conscientious and correct.

In order to reduce the breakage of the snake reed, attention should be paid to adjusting the concentricity error and angle error between the two shafts, and the value should be as small as possible than the design requirement.Improve the quality of the spring leaf.Pay special attention to material, hardness, heat treatment quality, etc. After heat treatment, there should be no defects such as cracks, and pay attention to removing sharp corners and sharp edges on the reed and tooth corner); improve the processing quality of arc tooth surfaces.Choose lubricating grease reasonably, not use thinner lubricating oil, but use aluminum disulfide lubricating grease with higher viscosity.To control the load, do not use overload; reduce the frequent effect of braking noise, especially emergency braking.When updating, a new type of elastic rod-pin coupling should be used.

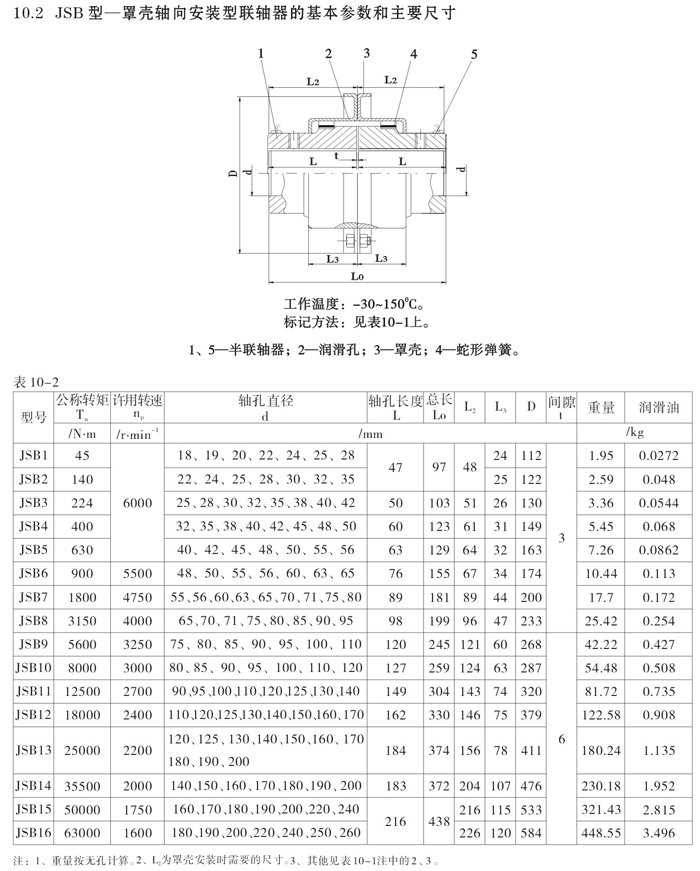

Technical parameters of JS B serpentine spring coupling: