Detailed installation tutorial of serpentine spring coupling

The serpentine coupling is divided into two types, transverse stiffness and variable stiffness, which are mainly determined by the following two shapes and spring contact teeth.

The serpentine coupling has a straight tooth profile.The distance between the contact points of the serpentine spring and the tooth will not change due to the deformation of the serpentine spring, and the rigidity will not change.The relative rotation angle of the two halves of the coupling is linearly related to the transmitted torque.

蛇形联轴器轴齿形为弯曲:轻负载时,弯曲弹簧的笔直部分基本上与所连接的轴平行。随着载荷的增加,弯曲弹簧的变形增加,与齿的接触弧面也增大,与齿的接触点之间的距离越来越短,并且刚度增大。联轴器的两个半部的相对旋转角度与传递的扭矩呈非线性关系,这是一个可变刚度的曲折式弹簧联轴器。线性齿形易于加工且成本低廉,但仅适用于传递扭矩变化较小的工作条件。曲线齿联轴器适用于大扭矩变化以及正负工况,并具有良好的缓冲效果,但弧形齿形的制造难度较小,制造成本较高。

蛇形联轴器具有许多的优良性能,例如:减震性能优,设备使用的时间长;以及可以经受大范围的变动载荷,在工作中起动Safety;还有就是传动效 率 高,工作的状态稳定,运行可 靠;在使用过程中产生的噪音小,润滑性强;结构简单,装拆方便。

蛇形弹簧联轴器的详细安装教程:

1. Install the sealing ring and half sleeve

关闭电源,干净地擦拭与联轴器相连的两个轴,然后在半联轴器和密封圈上涂抹润滑脂。将密封圈放在轴上),无需加热冷装快 速接头,而需加热过盈配合。

2.使用两个联轴器调节和对准标尺测量两个轴套之间的间隙,对准条件和同轴条件。调节偏差在安装联轴器的允许范围内。调整范围包括角度偏差。平行偏差和浮动偏差。对准后,联轴器提供长的使用寿命和少的联轴器维护。

3. Install the serpentine spring

Before installing the serpentine spring, fill the groove between the coupling teeth with long-term lubricant, and then fix the spring on the coupling tooth groove with wood.Gently fasten the teeth of the beating hammer (note that all the gaps in the installation spring point in the same direction, which helps the anti-rotation block to properly contact the cover).Then scrape off any grease on the outside of the spring.Under normal circumstances, refuel every 6 months.

4. Install the coupling cover

将联轴器密封环放在轴套上的适当位置,将其插入外壳下半部分的凹槽中,安装垫片,然后安装上盖的上半部分。合上外壳并拧紧螺丝。在联轴器正常工作之前,请确 保所有零件均已正确安装,联轴器已牢固地连接至轴,并且油塞已安装在注油孔中。

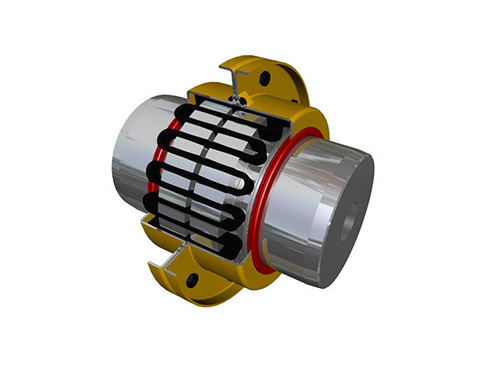

Serpentine spring couplingIt uses serpentine springs divided into one or several groups and is embedded in the teeth on the flange of the two-part coupling to realize the connection of the two halves of the coupling, in order to prevent the serpentine spring from being thrown out under the action of centrifugal force. And to avoid dry friction between the serpentine spring and the tooth contact, it needs to be covered with a closed shell and filled with lubricating oil or grease.