Installation steps and precautions of serpentine spring coupling

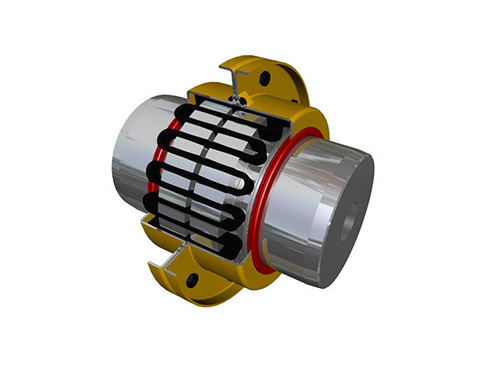

蛇形弹簧联轴器是一种结构的金属弹性联轴器。它以蛇形弹簧片轴向嵌入两半联轴器的齿槽内,来实现原动机与工作机的联接,由于簧片的特 殊性能,从而很大程度上避免了原动机与工作机的共振现象,使用寿命远高于非金属弹性元件联轴器;簧片所接触的齿面为弧形,接触面的大小随传递扭矩的大小而变化,因而它能承受大的载荷变动量,经测定其短时超载能力为额定扭矩的2~3倍,传动效率达99.5%,运行可 靠;且蛇形弹簧联轴器的结构简单,装拆方便,允许有较大的安装偏差,适用于冲击式的碎煤机、蛇形弹簧联轴器碎石机、曲柄往复运动、矿山、重型机械、减速机等。蛇形弹簧联轴器是当今国 际机械领域的轴联接传动部件,也是一种非常通用的轴联接传动部件,它广泛应用于各种机械及设备的轴传动,凡是有马达与轴相连、马达与减速箱相弱或轴与轴相联的地方都可应用。我国许多大型企业引进的成套进 口设备的轴连接都采用它作为传动部件,蛇形弹簧联轴器具有许多法兰盘轴联接无法比拟的优点,如:传动精 度 高、吸振、噪音小、运转平衡、安装便捷,对被联接的两轴轴线平行度、同心度、方向误差、偏角误差等要求不高,蛇形弹簧能根据载荷变化自动调节其刚性大小。

蛇形弹簧联轴器齿式为曲线型:负载较小时,Serpentine spring coupling的直线部分与被联接的轴线基本平行;负载增大时,蛇形弹簧的变形增大,与齿的接触弧面亦增大,而与齿接触点之间的距离越来越短,刚度增大,两半联轴器的相对转角与所传递的转矩为非线性关系,属于变刚度蛇形弹簧联轴器。

The linear tooth profile is easy to process and low in cost, but it is only suitable for working conditions with small changes in the transmission torque.Curved tooth couplings are suitable for large torque changes and positive and negative working conditions, and have a good cushioning effect, but the curved tooth shape has poor manufacturability and high manufacturing costs.

蛇形弹簧联轴器在安装使用和维护过程中有什么注意事项呢?下面为大家一一道来。

蛇形弹簧联轴器的安装步骤

1. Install the half-piece coupling on the shaft

(1) According to the size of the coupling, measure the actual (composition) elements of the shaft and the hole, and draw the line of the loading end position according to the regulations.

(2) Hammering method.Used for small size and clearance fit.First apply lubricating oil on the fit, place the key in the keyway, align the half-piece coupling into the shaft, and hit it with a hammer (preferably hit on the middle pad) until it is installed in the final position.

(3) Press assembly.Used for interference fit. When the interference is large, use the temperature difference method to fit the press assembly.The temperature difference method assembly is to heat and expand the hole (half coupling), and then install it on the shaft.You can use lubricating oil to heat in the heating box, or use steam heating, electric heating, etc., or use the cooling shaft to reduce the diameter, and then install the coupling.The coolants used for cold charging include liquid nitrogen (cooling temperature can reach -190~195℃), liquid ammonia (cooling temperature can reach -120℃), dry ice plus alcohol and acetone (cooling temperature can reach -75℃).

2. Coupling alignment connection

After the coupling is installed on the journal, the two halves of the coupling are preliminarily aligned by adjusting the shim, so that the centers of the two shafts are roughly aligned, and the end faces of the two coupling halves are initially parallel, and then the bolts are put on to prepare for coaxial Degree adjustment.