The characteristics and problems of serpentine spring coupling

蛇形弹簧联轴器适用于传递转矩变化较小的工况条件,在使用中可能会遇到振动大的问题,下面给大家分享蛇形弹簧联轴器应用中振动大怎样解决?

1. The vibration of the bearing and all directions are dominated by power frequency, with obvious double frequency components.Whether there is an obvious bearing failure frequency, it indicates that the bearings are not faulty and are installed and lubricated well.

2. According to on-site measurement data, the vibration of the non-drive end (impeller side) of the fan is less than the vibration of the drive end. The vibration of the two fans is not caused by the unbalanced mass of the serpentine spring coupling of the impeller itself or the unbalanced mass of the fan rotor after installation. of.

3. Whether there is an obvious passing frequency of the blades, and the field test has confirmed that the fan vibration has nothing to do with the opening of the baffle, indicating that the flow part of the fan is normal.

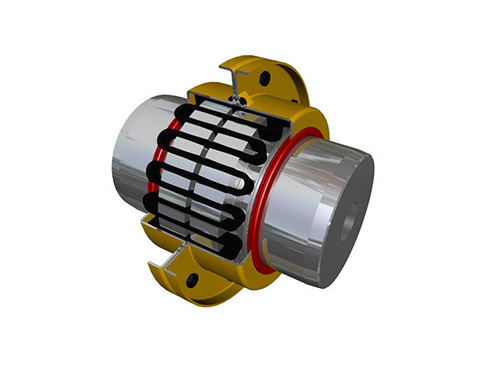

Characteristics of serpentine spring coupling

1. The coupling is axially embedded in the two halves with a serpentine spring leaf for more than 36%.The serpentine spring leaf of the trapezoidal section is made of spring steel, which has undergone strict heat treatment and processing. It has good mechanical properties, so that the service life of the coupling is much longer than that of the non-metal elastic element coupling (such as elastic sleeve pin , Nylon rod pin coupling) greatly increased.

2. The tooth surfaces of the two half couplings in contact with the reeds are arc-shaped. When the transmission torque increases, the springs will deform along the tooth arcs, so that the force points of the two half couplings on the reeds are close .The contact point between the reed and the tooth surface, that is, the change of torque, changes with the size of the transmitted torque, and its transmission characteristics are variable stiffness.So it has better than normalSerpentine spring coupling能承受大的载荷变动量。传动力使簧片沿齿弧变形时所产生的缓冲作用,尤其在机器起动时或冲击载荷时,于程度上有保护配套机件的特性。

3. The transmission efficiency of the coupling is determined to reach 99.47%, and its short-term overload capacity is twice the rated torque.

4. The aluminum alloy casing protects the spring from being thrown out during operation, and the casing is filled with butter, which not only makes the lubrication good, but also makes the noise when the reed engage is absorbed by the butter damping.

5. The whole machine has few parts, small size and light weight. The spring leaf designed as a trapezoidal cross-section and the trapezoidal tooth groove are particularly convenient and tight, so that the assembly, disassembly and maintenance are easier than ordinary couplings.

6. Since the spring leaf and the tooth arc surface are in point contact, the coupling can obtain greater flexibility.It can be installed to work normally under conditions of radial, angular and axial deviations at the same time.

Snake spring coupling is a mechanical part used to connect two shafts (driving shaft and driven shaft) in different mechanisms so that they can rotate together to transmit torque.In high-speed and heavy-load power transmission, some couplings also have the function of buffering, damping and improving the dynamic performance of the shafting.The coupling is composed of two halves, which are respectively connected with the driving shaft and the driven shaft.The general power machine is mostly connected with the working machine by means of a coupling.

蛇形弹簧联轴器出现的问题

1. The serpentine spring coupling will inevitably have such problems and such problems during use. Among them, the possible problems are mostly vibration.

2. The advantages of this coupling are its small radial size, large carrying capacity, and long shaft transmission under low-speed and heavy-load conditions. The dynamically balanced gear coupling can be used for high-speed transmission, such as gas turbines. Shaft transmission.

3. The whole machine has few parts, small size and light weight. The spring leaf designed as a trapezoidal cross-section and the trapezoidal tooth groove are particularly convenient and tight, so that the assembly, disassembly and maintenance are easier than ordinary couplings.

4. Since the angular compensation of drum gear couplings is greater than that of straight gear couplings, drum gear couplings are commonly used. Straight gear couplings are obsolete products, and those who choose it should try not to Optional.

5. Since the spring leaf and the tooth arc surface are in point contact, the coupling can obtain greater flexibility.It can be installed to work normally under conditions of radial, angular and axial deviations at the same time.