Jaw Coupling

SS Type Stainless Steel Curved Jaw Couplings

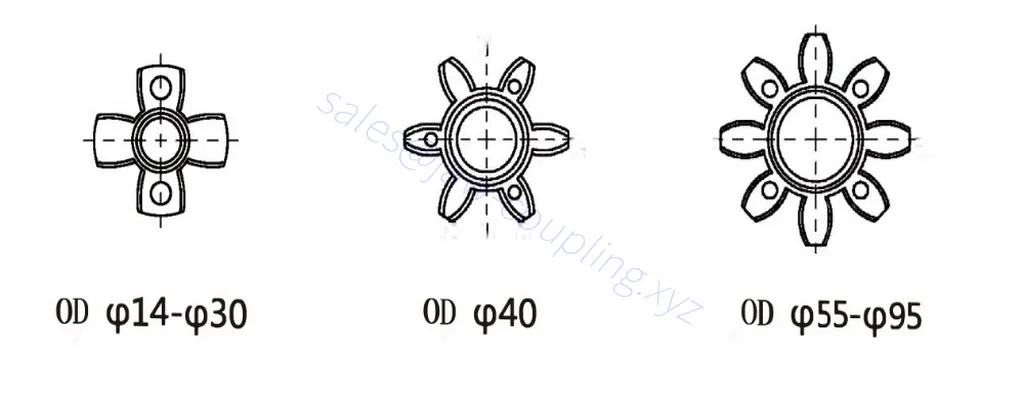

The Curved Jaw couplings can be used in many applications and as an all-purpose coupling. The basic design of the Curved Jaw allows for a higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it a high torque capacity and reduces edge pressure. It will accommodate axial, radial, and angular shaft misalignments.

As one of the jaw coupling manufacturers, suppliers, and exporters of mechanical products, We offer jaw coupling and many other products. Please get in touch with us for details.

Mail:[email protected]

The Curved Jaw couplings can be used in many applications and as an all-purpose coupling. The basic design of the Curved Jaw allows for a higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it a high torque capacity and reduces edge pressure. It will accommodate axial, radial, and angular shaft misalignments.

The hubs are produced from various materials, including aluminum, gray, iron, steel, sintered, and stainless steel. The spider elements are available in different durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles, including shock loading and minimizing torsional vibrations in the system.

Product Detail Pictures:

|

|

Coupling Specification

|

Model

|

Bore size (mm)

|

RatedTorque (N.m)

|

MaxTorque(N.m)

|

Max speed

|

Outer Diameter (mm)

|

Length (mm)

|

Bore Tolerance (mm)

|

|

HS -TCN-14C

|

3~7

|

0.7

|

1.4

|

45000

|

14

|

22

|

+0.6~0

|

|

HS-TCN-20C-R

|

4~11

|

1.8

|

3.6

|

31000

|

20

|

30

|

+0.8~0

|

|

HS-TCN-30C-R

|

6~16

|

4

|

8

|

21000

|

30

|

35

|

+1.0~0

|

|

HS-TCN-40C-R

|

8~28

|

4.9

|

9.8

|

15000

|

40

|

66

|

+1.2~0

|

|

HS-TCN-55C-R

|

9.5~32

|

17

|

34

|

11000

|

55

|

78

|

+1.4~0

|

|

HS-TCN-65C-R

|

12.7~38.1

|

46

|

92

|

9000

|

65

|

90

|

+1.5~0

|

Spider Characteristics

The curved jaw coupling includes two metal hubs and an elastomeric “spider” element. The spiders are available in

different hardness durometers, each easily identified by its color.

|

Hardness

|

Color

|

Material

|

Temperature Range

|

Applications

|

|

80 Shore A

|

Blue

|

Polyurethane

|

-50 ~+80. C

|

Excellent damping

|

|

92 Shore A

|

Yellow

|

Polyurethane

|

-40~+90 .C

|

Moderate damping, general applications

|

|

98 Shore A

|

Red

|

Polyurethane

|

-30 ~+90. C

|

High torque applications

|

|

64 Shore D

|

Green

|

Polyurethane

|

-50 ~+120. C

|

Higher torque, high temperature

|

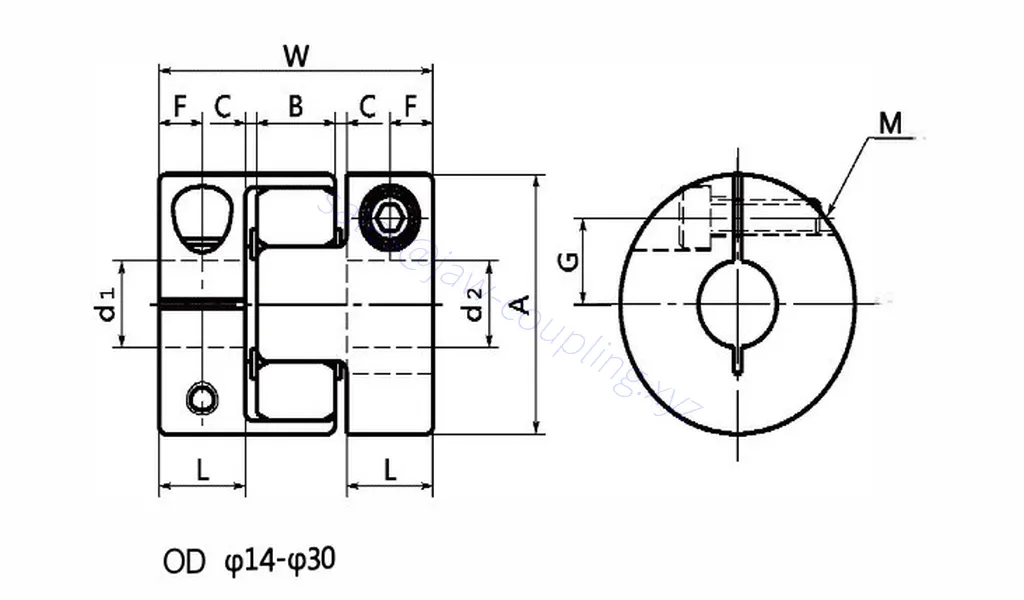

Coupling Measure Information

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

14

|

7

|

22

|

6

|

1

|

3.5

|

4/5

|

M2/M1.6

|

|

20

|

10

|

30

|

8

|

1

|

5

|

6.5/7.5

|

M2.5/M2

|

|

30

|

11

|

35

|

10

|

1.5

|

8.5

|

10/11

|

M4/M3

|

|

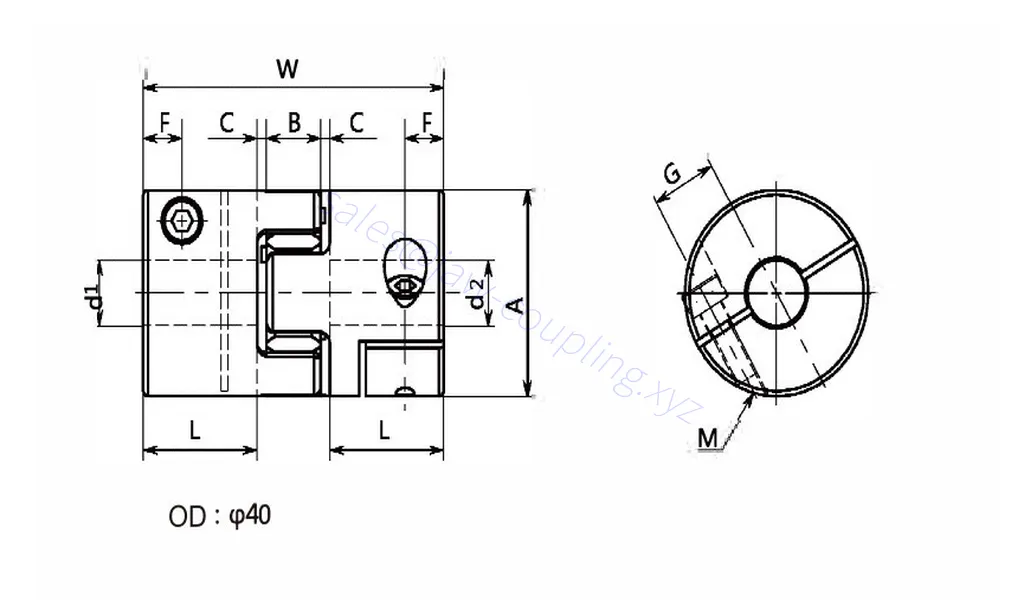

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

40

|

25

|

66

|

12

|

2

|

8.5

|

14/15.75

|

M5/M4

|

|

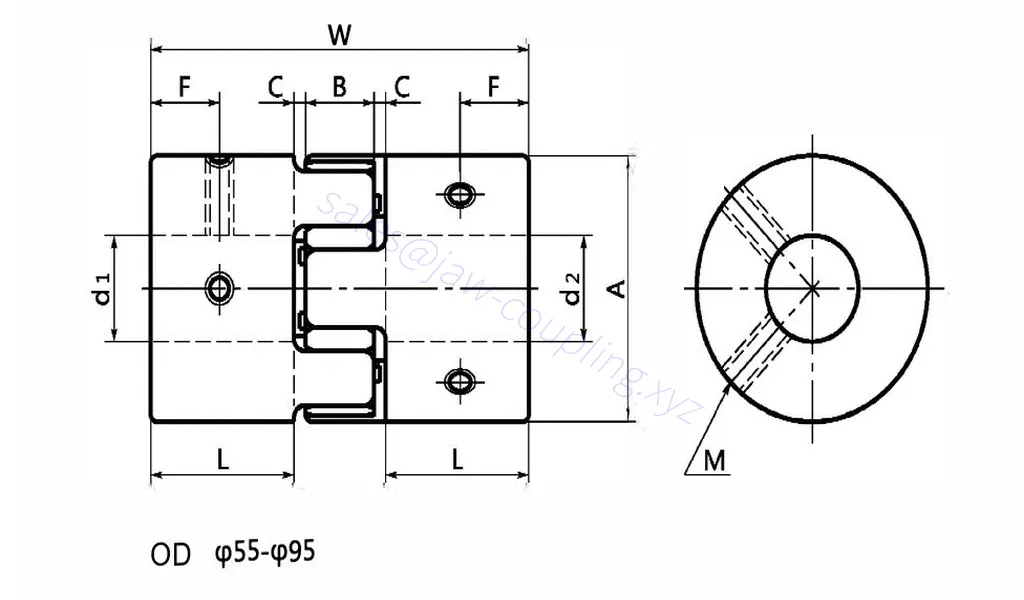

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

55

|

30

|

78

|

14

|

2

|

10.5

|

20/21

|

M6/M5

|

|

60

|

35

|

90

|

15

|

2.5

|

13

|

24/25

|

M8/M6

|

Company Profile

The company’s main products are all kinds of couplings for the machinery industry all over the world, such as radial elastic coupling, tired coupling, universal coupling, drum gear coupling, plum flower form flexible coupling, rigid coupling, Oldham coupling, roller chain coupling, diaphragm coupling, coupling column elastic sleeve pin couplings, elastic dowel pin, elastic dowel pin coupling, pump shaft coupling, etc.

The concepts of our company are live on quality and develop on honor. The coupling has the advantage of high quality, low price, and complete product models. Our company will be your best choice, and we look forward to cooperating with you.

Related Products

Jaw Coupling Video

FAQ

1: Are you a trading company or a manufacturer ?

We are a professional manufacturer of couplings and universal joints.

2:Why choose Transfer Precision Transmission ?

As a professional manufacturer of coupling and universal joints, we possess a skillful team of workers and designers To provide our customers with first-class services.

3: Can You Strictly Follow The Tolerance on The Drawing And Meet The High Precision?

Yes, we can, we can provide high precision parts and make the parts as your drawing.

4:How long does it take to delivery?

Generally, it is 1-2 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it depends on quantity.

5:How to deal with the parts received when they are found to be in poor quality?

A: In case of non- conformance, please contact us immediately, we will check the problems and have them reworked or repaired at the first time. If none of these works, we support a refund.