Jaw Coupling

XL Type High-Quality Jaw Flexible Couplings

Jaw couplings are compression coupling that controls motion by transmitting torque and damping vibrations that could cause damage to other system components. They are composed of a polyurethane-based elastomeric part called a spider that joins two hubs made of sintered metal, aluminum, standard steel, stainless steel, bronze, or iron. These three parts are press-fitted together, with a jaw from each hub fitting into the elastomeric element’s grooves.

As one of the jaw coupling manufacturers, suppliers, and exporters of mechanical products, We offer jaw coupling and many other products. Please get in touch with us for details.

Mail:[email protected]

Jaw couplings are compression coupling that controls motion by transmitting torque and damping vibrations that could cause damage to other system components. They are composed of a polyurethane-based elastomeric part called a spider that joins two hubs made of sintered metal, aluminum, standard steel, stainless steel, bronze, or iron. These three parts are press-fitted together, with a jaw from each hub fitting into the elastomeric element’s grooves.

|

|

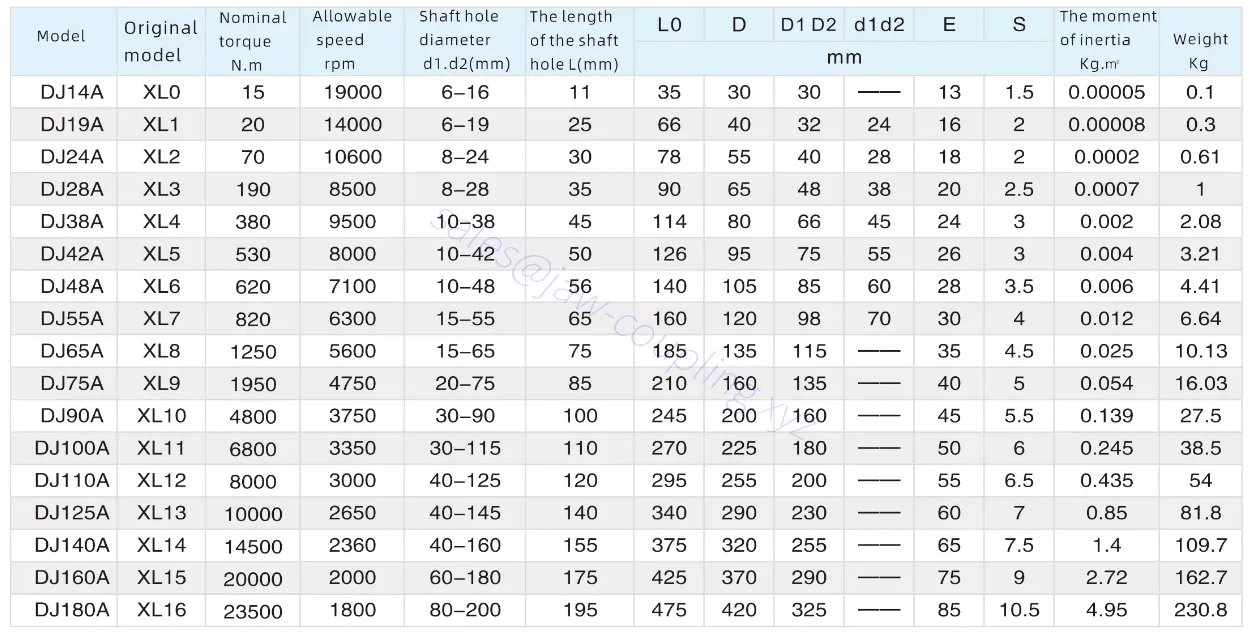

Product Specifications

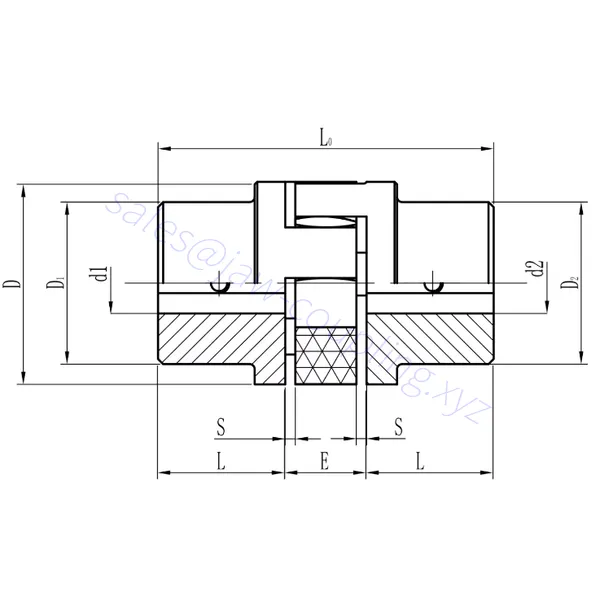

Design of Jaw Couplings

The elastomeric element is often referred to as a spider because of its shape-circular with an even number of legs jutting out. It serves to dampen impulse loads and minimize shock to a motor. The elastomeric material that the spider is made of is available in different degrees of hardness, giving the operator more control over how much vibration the coupling absorbs. The polyurethane used can be either soft, which provides better vibration dampening, or complex, which gives the spider more strength.

It can be customized to a specific application. The hubs have curved jaws that interlock and reduce the spider’s deformation, preventing backlash. These couplings are considered to fail safely because if the spider malfunctions, the jaws of the two hubs interlock and create direct power transmission so the vehicle can shut down safely. Jaw couplings perform best for applications requiring accuracy and a stop-and-go type of movement.

Jaw couplings are accurate, but still, they are not optimal for applications in which precise movements are required during exercise. Varying amounts of vibration absorption directly affect the settling time, where the system pauses briefly to perform an action or move quickly and precisely. If vibrations are mostly absorbed, the system does not hesitate before performing an action that increases the line’s speed.

Features of Jaw Flexible Couplings

Company Profile

The company’s main products are all kinds of couplings for the machinery industry all over the world, such as radial elastic coupling, tired coupling, universal coupling, drum gear coupling, plum flower form flexible coupling, rigid coupling, Oldham coupling, roller chain coupling, diaphragm coupling, coupling column elastic sleeve pin couplings, elastic dowel pin, elastic dowel pin coupling, pump shaft coupling, etc.

The concepts of our company are live on quality and develop on honor. The coupling has the advantage of high quality, low price, and complete product models. Our company will be your best choice, and we look forward to cooperating with you.

Related Products

Jaw Coupling Video

FAQ

1: Are you a trading company or a manufacturer ?

We are a professional manufacturer of couplings and universal joints.

2:Why choose Transfer Precision Transmission ?

As a professional manufacturer of coupling and universal joints, we possess a skillful team of workers and designers To provide our customers with first-class services.

3: Can You Strictly Follow The Tolerance on The Drawing And Meet The High Precision?

Yes, we can, we can provide high precision parts and make the parts as your drawing.

4:How long does it take to delivery?

Generally, it is 1-2 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it depends on quantity.

5:How to deal with the parts received when they are found to be in poor quality?

A: In case of non- conformance, please contact us immediately, we will check the problems and have them reworked or repaired at the first time. If none of these works, we support a refund.