Product Description

Quick Details

| Applicable Industries:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Energy & Mining, Other |

Customized support:

OEM, ODM |

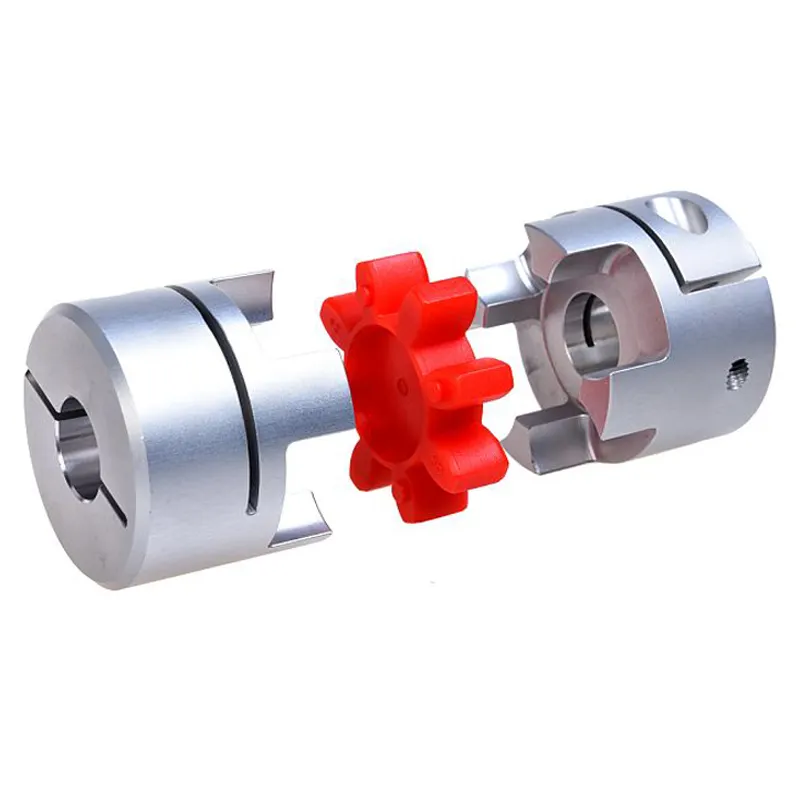

| Type:Jaw Coupling | Surface treatment: BLACK |

| Place of Origin:ZheJiang , China | Brand Name:REACHJY, REACHJY |

| Application:transmission | |

| Certification:Reach | |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Use of Jaw Couplings in Food Processing and Pharmaceutical Industries

Jaw couplings can be used in food processing and pharmaceutical industries under certain conditions and with the appropriate materials and design considerations. These industries have strict regulations and requirements regarding hygiene, contamination prevention, and cleanability. Here are some key factors to consider:

- Material Selection: For applications in food processing and pharmaceutical industries, jaw couplings must be made from materials that meet FDA and/or other regulatory standards for food contact and pharmaceutical use. Stainless steel or FDA-approved plastics are commonly used in such applications.

- Cleanability: The design of the jaw coupling should allow for easy cleaning and sanitization. Smooth surfaces and minimal crevices help prevent the accumulation of debris and bacteria. Hygienic designs are crucial to ensure compliance with industry standards.

- Sealing: Proper sealing is essential to prevent any lubricants or contaminants from escaping the coupling and coming into contact with the processed materials. Seal materials must be compatible with the substances used in the industry.

- Corrosion Resistance: In food processing and pharmaceutical environments, equipment is often subjected to aggressive cleaning agents and chemicals. Jaw couplings must be corrosion-resistant to withstand these harsh conditions and maintain their performance over time.

- Compliance with Regulations: Industries such as food processing and pharmaceuticals have specific regulatory standards, such as those set by the FDA (Food and Drug Administration) or other relevant authorities. The jaw couplings used in these applications must meet all necessary regulations to ensure product safety and consumer confidence.

It is important to note that while jaw couplings can be suitable for certain applications in food processing and pharmaceutical industries, it is essential to work closely with coupling manufacturers and suppliers to ensure that the selected couplings meet all industry-specific requirements and standards. Additionally, regular maintenance and inspection should be carried out to ensure the couplings continue to perform as expected and comply with hygiene and safety regulations.

How does a jaw coupling help in torque and rotational speed control?

A jaw coupling plays a vital role in torque and rotational speed control by facilitating efficient power transmission while compensating for misalignments and dampening vibrations. Here’s how a jaw coupling helps in achieving torque and rotational speed control:

- Torque Transmission: Jaw couplings are designed to transmit torque between two shafts with minimal power loss. The elastomer spider, which acts as the flexible element between the two coupling hubs, efficiently transfers torque from one shaft to the other. This precise torque transmission is essential in maintaining consistent rotational motion and controlling the speed of the driven equipment.

- Misalignment Compensation: In rotating machinery, misalignments between the motor and driven equipment are common due to factors like installation errors, thermal expansion, or shaft deflection. Jaw couplings can handle both angular and parallel misalignments. By accommodating these misalignments, jaw couplings ensure smooth operation and prevent unnecessary stress on the equipment, thus contributing to torque and rotational speed control.

- Vibration Damping: Vibrations are an inherent characteristic of rotating machinery and can affect torque and rotational speed stability. The elastomer spider in the jaw coupling acts as a damping element, absorbing and dissipating vibrations. This vibration damping capability reduces the risk of speed fluctuations and enhances overall system stability during operation.

- Start-Up and Overload Protection: During start-up or when the driven equipment experiences sudden overload conditions, there may be spikes in torque and rotational speed. Jaw couplings, with their torsional flexibility, can absorb these sudden torque variations, protecting the equipment from damage and providing smoother start-up and operation.

The combination of precise torque transmission, misalignment compensation, vibration damping, and overload protection makes jaw couplings effective in achieving torque and rotational speed control. However, it is essential to choose the appropriate jaw coupling size and material for the specific application to ensure optimal performance and reliability.

For applications that require even higher torque capacity or stricter speed control, specialized coupling types like gear couplings or servo couplings may be more suitable. These couplings offer advanced features for precision motion control and torque transmission in more demanding applications.

Materials Used in Manufacturing Jaw Couplings

Jaw couplings are commonly made from various materials, each offering different properties and suitability for specific applications. Some of the commonly used materials include:

- Polyurethane (PU): PU jaw couplings are known for their flexibility, high elasticity, and resistance to abrasion. They are ideal for applications requiring vibration dampening and shock absorption.

- Aluminum: Aluminum jaw couplings are lightweight, corrosion-resistant, and have good thermal conductivity. They are commonly used in low-to-medium torque applications.

- Steel: Steel jaw couplings offer high strength and durability, making them suitable for heavy-duty applications with high torque requirements.

- Stainless Steel: Stainless steel jaw couplings are resistant to corrosion and are often used in applications where there is exposure to moisture, chemicals, or harsh environments.

- Bronze: Bronze jaw couplings are known for their excellent wear resistance and low coefficient of friction, making them suitable for applications with high-speed and low lubrication.

- Acetal: Acetal jaw couplings provide good chemical resistance and low moisture absorption, making them suitable for applications where chemical exposure is a concern.

- Nylon: Nylon jaw couplings offer good strength, flexibility, and resistance to wear and chemicals, making them suitable for various industrial applications.

The choice of material depends on factors such as torque requirements, environmental conditions, operating speeds, and budget considerations. Engineers and designers select the appropriate material to ensure that the jaw coupling can perform optimally and withstand the demands of the application.

editor by CX 2023-12-19